How a Global Foods Manufacturer Increased Production Efficiency and Reduced Job Errors with Advanced Analytics and Machine Learning

Download the Case Study

Overview

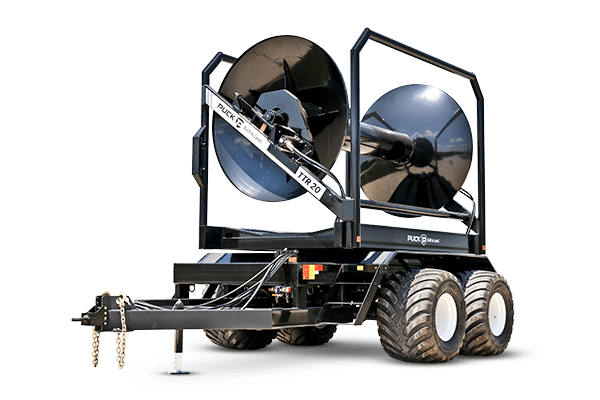

A large Midwest-based foods manufacturer began to anticipate the detrimental production issues they could face if they were unable to more effectively monitor the status and efficiency of machinery applications on the manufacturing floor. Production throughput at the company is hindered when software program jobs take longer than necessary to complete, and there lacked a manageable process to accurately monitor and detect long-running jobs across the 1000+ unique job types. They appointed Zirous to perform analysis on their program runtime data to determine if their current process was creating effective results, to define the appropriate runtime of each type of job, and to explore if machine learning could predict the likelihood of jobs failing at the time of scheduling. Zirous was able to uncover insights into these numbers and make recommendations to alleviate the manufacturer’s production inefficiencies and automate future processes for proactive cost savings.

The Challenge

A global foods manufacturer presented an ongoing struggle managing more than 1,000 unique manufacturing jobs within their Oracle Concurrent Manager system. These jobs were producing hundreds of unique products and recipes across 24 sprawling production facilities throughout the world. While the management system allows for unique flags and alerts to be set for each job, knowing what each job’s runtime threshold limit should be and then maintaining those settings individually across that many job types was not feasible given their current capabilities. Jobs that fail to complete successfully, take much longer than expected, or require more resources than expected have negative impacts to the company’s production rate, leading to decreased revenue, increased costs, and an inefficient use of personnel and resources.

With over 1.4 million jobs being scheduled each year, identifying and canceling the errant jobs proved to be a challenge. In an effort to draw user attention to jobs that could be in need of reviewing, the company began sending an alert to a user anytime a job request was running for more than two hours. However, the generic nature of the alert meant that some jobs with a legitimate need to run for more than two hours would fire unnecessary alerts. The company sensed that alert fatigue had developed among users due to an abundance of unsubstantiated investigation on jobs that were running as planned. This universal setting did not account for how long the jobs had run in the past or how long they should run for production to proceed without delay. The company needed ways of determining more appropriate time frames for each job and automating tailored alerts to overcome the infeasibility of maintaining custom settings.

The Solution

Zirous first performed detailed statistical analysis on all job requests across a full twelve-month timeframe. We discovered that:

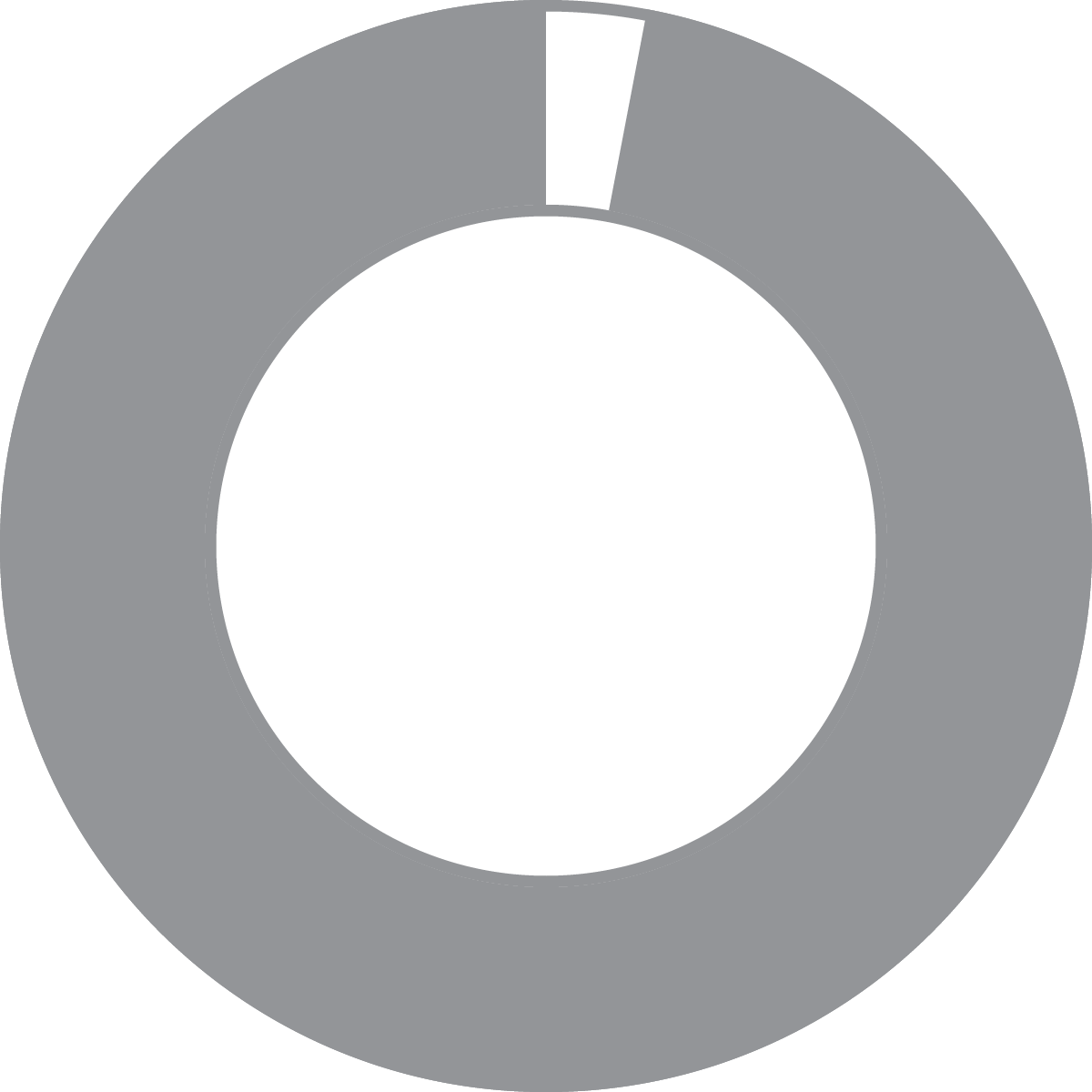

97% of received alerts were not acted upon

83% of terminated requests took place before an alert was ever fired

39% of alerts were flagged on jobs that, statistically, could legitimately take longer than 2 hours to complete

only 0.43% of requests with excessively long runtimes were terminated

This confirmed to the manufacturer that their users were experiencing alert fatigue and their current process for managing these job requests was not effective.

Next, Zirous created a machine learning model across four years’ worth of job data to predict, at the time of scheduling, if a job would complete successfully.

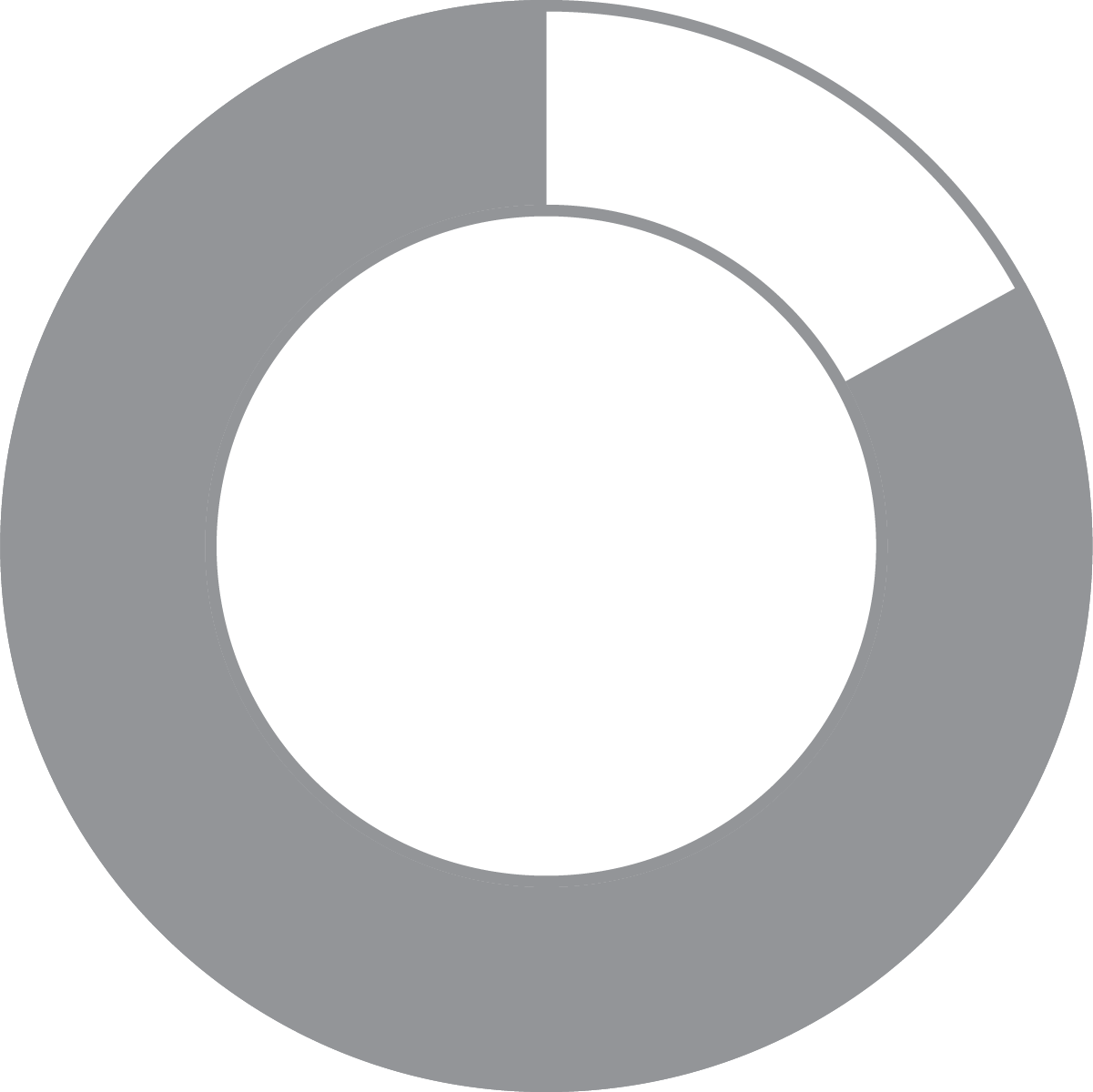

The model created by Zirous was able to correctly predict 69% of the requests that would need to be cancelled, while only triggering a false alarm on 0.009% of requests.

Armed with this detailed information, Zirous’ machine learning team was able to provide additional recommendations to the foods manufacturer:

Immediate impact:

- Manually set a tailored runtime alert for the most problematic job types to the recommended value Zirous provided based on our

statistical findings.

Next steps:

- Script an automated process that sets and updates tailored alerts for all job types using the statistical analysis performed on

historic runtimes. - Operationalize a machine learning model, fine-tuned with increased domain knowledge and data, to proactively warn a user

if they are scheduling a job that will not complete successfully. This would allow for heightened awareness and investigation to

identify root causes of the problematic jobs.

The Impact

The greatest impact of Zirous’ work with this foods manufacturer was providing proactive insight into mitigating costly business inefficiencies. This proof of value demonstrated just how useful machine learning and advanced analytics could be for their business and its bottom line. With the insights the Zirous machine learning team uncovered and the recommendations for next steps provided, the company can greatly increase their efficiency and avoid the detrimental effects of their manufacturing applications going down. This is also creating a better employee and user experience due to the elimination of alert fatigue and wasted time on investigation of normally running jobs.

Quick Facts

Company

- Global foods manufacturer headquartered in the Midwest

- Annual sales of over $5 billion

- 24 manufacturing plants across the globe

- 1.4 million production jobs run in 2018

Technologies Involved

- Python

- Jupyter

Highlights

- A global foods manufacturer was facing challenges managing more than 1,000 production jobs within their Oracle Concurrent Manager system.

- The manufacturer created an alert system to notify production team members of hanging jobs causing downtime and delays.

- Team members began to face alert fatigue, and 97% of alerts were not acted upon, with 39% of alerts taking place on jobs that may not need them.

- Zirous performed analysis to determine how to categorize job types and create a system of more accurate alerts for each job.

- Zirous also prescribed tangible next steps in the manufacturer’s road to production success using operationalized machine learning models.